-40%

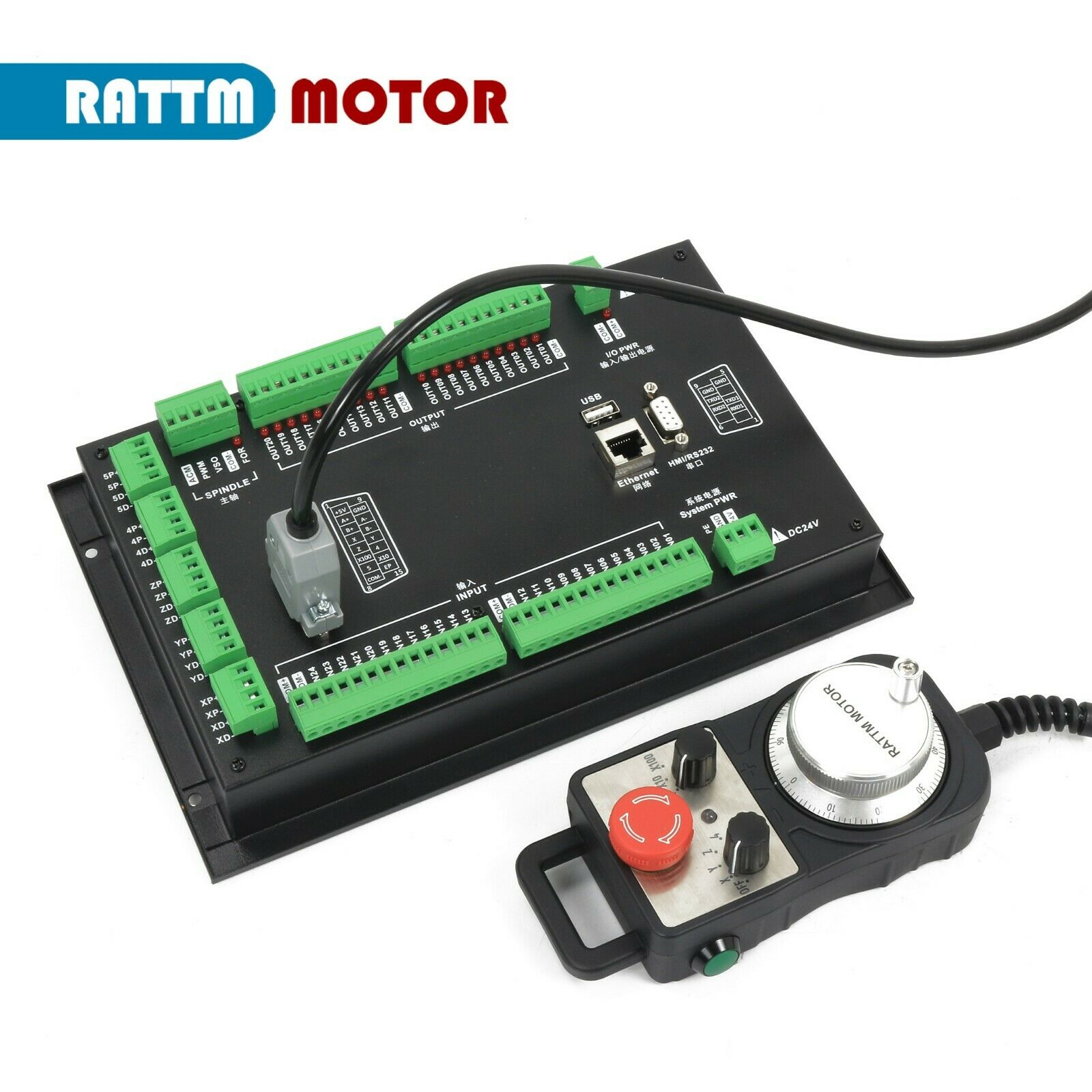

PLC 4 Axis Off-line CNC Motion Controller DDCS Expert With MPG Handwheel

$ 210.67

- Description

- Size Guide

Description

Package include:1 x DDCS Expert

1 x handwheel with emergency stop

1 x Cable

Ship to US ,from China. Ship to EU countries, can be sent from DE warehouse.

English manual is sented via e-mail,after u purchase,pls leave ur e-mail address.

1.1 Product Brief Introduction

Digital Dream is a numerical control company specializing in the research, development

and production of various CNC (Computer Numerical Control) systems since 2008. Digital Dream

aims to combine high quality and high reliability with affffordability.

The DDCS Expert is a 3~5 axes motion controller for open or close stepper and servo systems

with 7/10.2 full color display screen. The highest output pulse per axis is 1MHz. The users can

self-defifine the functional keys. This controller supports multiple spindle mode, support straight

Tool Magazine, gantry type Magazine, disk type magazine. The Operation system interface even

though very comprehensive, can be learned in very short time.

The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM

controls the human-computer interface and code analysis and the FPGA provides the underlying

algorithms and creates the control pulse. This guarantees reliable control and easy operation.

The internal operating system is Linux based.

The DDCS Expert can be used for many styles and types of CNC machines. Lathes, Routers,

Pick&Place and Mills, lathe and cutters are just a few examples. The DDCS Expert operates as a

Stand Alone system without the need of a computer. This guarantees high precision, accuracy

and reliability.

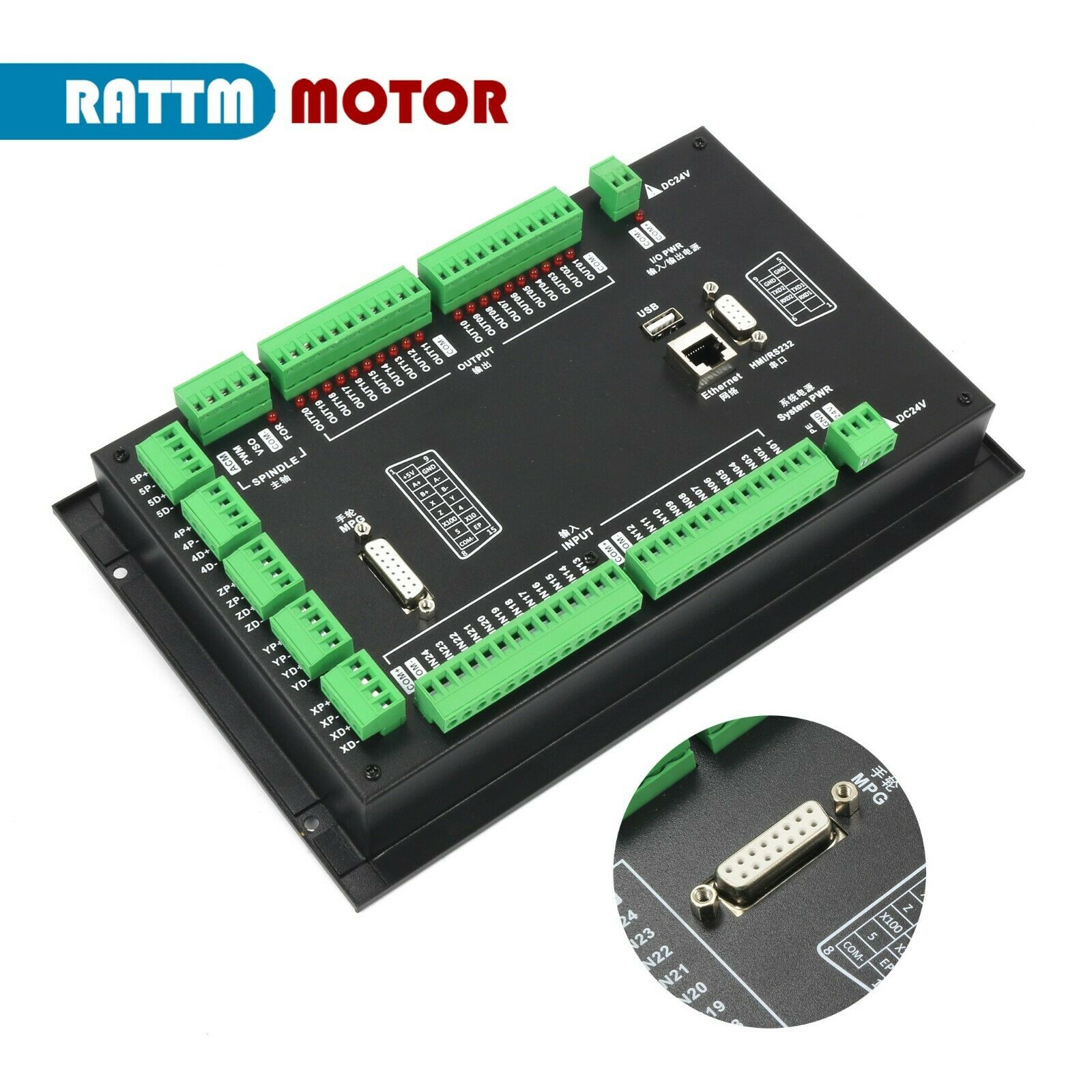

1.2 DDCS-Expert Brief technical feature:

axis circular interpolation;

1) Max. 5 Axis; 1M Hz output frequency for each axis; 2-4 Axis linear interpolation, any 2

2) 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys;

3) 24 photoelectric isolated digital inputs, 21 photoelectric isolated digital outputs;

4) Analog spindle control 0-10V spindle control, also support PWM Output;

5) Magazine type: Supports multiple spindle mode, support straight Tool Magazine, gantry

type Magazine, disk type magazine;

6) Probe Mode: Supprt Floating Probe and Fixed Probe;

tion, length compensation;

7) Backlash compensation methods: direction gap compensation, radius gap compensa-

8) Interpolation Algorithm: S type, circular hard algorithem, circular soft algorithm;

9) Language: Chinese, English;

10) Software Alarms: Program Error, operation Error, overtravel Error, Driver Error and so

11) Network: Support fifile share and online machining the remote fifiles by Ethernet;

output, and servo spindle output;

12) Spindle control mode support Multi-speed (3 lines 8 kinds speed), 0-10V Analog

13) Compatible with standard G-code, support popular CAD/CAM software, such as

ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

14) The control system can preview the processing path before machining, and it makes

the system more steady, working smoothy and precise;

15) Support high speed machining in continuous Polyline segment, system can choose a

most effiffifficient algorithm automatically from difffferent kinds Polyline segment algorithm;

16) Support un-limited size fifile for machining;

17) Support Pause Breakpoint resume, “Power Cut” recovery, Start from the specifific line;

18) Support time-lock function;

19) Support 4 kinds operation rights: visitor, operator, admin, super admin;

mode” and so on;

20) Support function of “Try cutting” (handwheel guiding) and “Single-stage processing

21) Support the fuction of Back to orignal point

21) The Power Supply for the controller is 24VDC, minimum Current is 0.5A;

22) The Power Supply for IO Port is 24VDC, minimum current is 0.5A; By the IO power

supply,system already supply the power to IO ports.So no need the external power supply.